GENERAL 4A-G INFO: by Phil Bradshaw

INTRODUCTION

The aim of this article is to explain the variations between the different engine generations to assist you in selecting the best one for your application, and provide some advice on conversion to RWD.

The 4AGE is arguably the best option available for installation in a small kit car – it is compact, powerful, reliable, plentiful and cheap. It is also easier and cheaper to convert to RWD than engines such as the 3SGE. The only real limitation is the standard upper horsepower limit of around 165 for factory engines, although 240 is achievable in Formula Atlantic trim, if your pockets are sufficiently well lined.

The 4AGE engine was designed from the outset to be the performance engine for the FWD Corolla/Sprinter range (AE82, AE92, AE101 and AE111 models), which have been its main home. It was also fitted to the first generation (AW11) MR2, RWD (AE86) Corollas (GT, Levin and Trueno, depending on the market) and the odd RWD (AA63) Celica. In simple terms the engine has been upgraded every 4 years, although some changes have occurred at the 2 year point, generally keeping in step with model changes and facelifts to the Corolla.

Given that it was introduced in May 1983 and that (I believe) production ceased in 1999, it is not surprising that there are a variety of engines around: five naturally aspirated versions, and three supercharged ones. Sadly there is no such thing as factory turbocharged versions or supercharged 20 valve models, although the good news is you can easily build one pretty much from factory parts.

The 4AGE itself displaces 1587cc and is in a belt driven 16 valve twin cam configuration, running multi-point fuel injection. No factory engines were produced with carburettors. All engines were produced in transverse configuration with a transaxle, with the exception of the early (1983-87) RWD units fitted to some Corolla GTs, Levins, Truenos and Celicas. These engines are becoming increasingly rare but remain the easiest option for RWD installation, despite the fact that they produce less horsepower than later models and are all getting pretty tired by now. The saving grace is that all later generations of the engine will literally bolt up to a RWD gearbox, opening up the availability of a wide range of power outputs.

The downside comes from the fact that the newer generation engines are optimised for transverse configuration only and in most cases require varying degrees of modification to fit into a RWD body shell. Bolting a FWD 4AGE to a RWD gearbox and mounting the unit in a car is the easy part - the difficulty lies in getting the intake systems, radiator plumbing and (in some cases) distributors to fit.

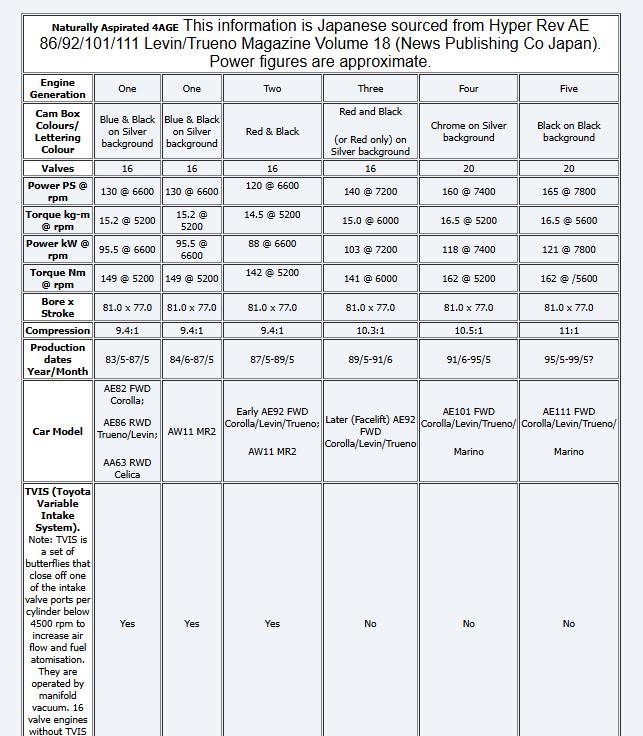

I will now describe in brief terms the features of each generation of engine; full details of the variations are included in a table at the end for easier reference. I will also describe conversion of later engines to RWD. The methods I propose are what I consider to be the easiest, cheapest and most effective, but are by no means the only way to achieve the end result. Finally I will describe some of the more common modifications that are possible. On with the show.

"ENGINE TYPES"

First Generation 4AGE (83.5-87.5)

The first generation 4AGE was introduced in May 1983 and remained in production until May 1987. Engines can be roughly aged by the year printed on the spark plug leads – provided they are original. The engine is externally identified by silver cam covers with black and blue lettering, hence they are often referred to as 'blue and black tops'. This generation was produced in transverse form (AW 11 MR2 and AE 82 FWD Corolla) and RWD longitudinal from (AE 86 Corolla GT/Corolla Levin/Sprinter Trueno and AA 63 Celica). Transverse engines have the throttle body at the flywheel end of the inlet manifold while RWD have the inlet at the pulley end.

This generation features the Toyota Variable Intake System (TVIS), which is a set of four butterflies located in the inlet system next to the head. These butterflies remain shut below approximately 4500 RPM, effectively limiting airflow to one valve per cylinder, increasing the air speed and thus improving mid range torque. They are opened above this speed by the ECU via a small plastic vacuum tank and solenoid triggered actuator located under the inlet manifold. The feel is similar to a second throat opening on a carburettor. These engines develop in the vicinity of 88 kW in transverse configuration, but around 95 in some RWD models. I am not sure if this applies to all RWD models, or only those that do not run a factory exhaust sensor (such as the NZ new leaded petrol versions). RWD versions are all MAP sensored; some Japanese sourced transverse engines may be air flow meter equipped.

These engines have a weaker block and crank than later versions, and suffered from the crank pulley bolt coming loose, allowing the pulley to damage the crank and key way. Later model engines have a separate bolt and washer, whilst these first generation engines have an integral unit.

Second Generation 4AGE (87.5-89.5)

The second generation engines were released in May 1987 and are identified by silver cam covers with red and black writing, hence ‘red and black top’. Effectively these engines retained the previous head and TVIS, but employed an all new, stronger block (identified by seven vertical ribs as opposed to three on the 1st generation engines), heavier duty crank and conrods. These engines remained on the market until May 1989 and have similar performance to the first generation transverse models, but are more robust. These engines were only produced in FWD, hence all throttle bodies are located at the flywheel end of the engine.

A supercharged model (4AGZE) was also released. This engine has unpainted cam covers. The engine fitted to MR2s has the supercharger outlet to the intercooler facing the flywheel end of the engine block and a normal distributor. The model fitted to the FWD Trueno/Levin has the intercooler plumbing facing upwards (the intercooler mounts on top of the cam covers) and has a crank angle sensor fitted in place of the distributor. This engine is fitted with twin coil packs instead of a conventional distributor arrangement. Power output is 107 kW for both supercharged configurations.

All 2nd generation engines are equipped with an air flow meter and were fitted to AE 92 Corolla/Levin/Truenos and face-lifted AW 11 MR2s.

Third Generation 4AGE (89.5-91.6)

The next generation engines were introduced in May 1989 and remained in production until June 1991. These engines effectively retained the heavier duty block but added a new head with smaller intake ports, hence the TVIS was discontinued. Some engines have silver cam covers with red lettering only (and so are called red tops), while others continued with black and red lettering. The easiest way to identify these engines is by the ribbing on the top surface of the intake manifold (earlier models have smooth tops) and an external oil drain from the head to the sump, located on the inlet side behind #4 inlet port. The sump is slightly different to earlier models.

These engines all have oil cooled pistons and the ignition leads run underneath a cover between the cam covers. Power is increased to 100 kW and all engines are MAP sensored. I believe these engines all feature a knock sensor, located near the top of the block on the inlet side between #2 and #3 cylinders. This is the final naturally aspirated 16 valve variant produced.

The 4AGZE has the same additions and utilises the twin coil distributor less ignition system, as it was only available in FWD AE 92 Levins and Truenos. Power increased to 120 kW and the supercharger has a smaller diameter pulley compared to the earlier version.

Fourth Generation 4AGE (91.6-95.5)

The fourth generation, released June 1991, saw the demise of the 16 valve in naturally aspirated form and its replacement with the 20 valve. This engine utilises the same block as the previous generation, however, an all new head is fitted that features three inlet valves per cylinder and variable inlet cam timing. The pistons are different to suit the clearances required around the extra valve. Knock sensing and oil cooled pistons are utilised to cope with the higher compression over the earlier models. The distributor is mounted off the back of the exhaust cam. The engine is fitted with 4 throttle bodies and is air flow meter sensored. This engine was sold new in Japan only, and also has factory tubular headers. Power output is 120 kW but with less torque than the 4AGZE.

Pre facelift engines (91/5-93/5) can be identified by the throttle linkage mechanism, in that an additional horizontal bell crank arm is fitted between where the throttle cable attaches and the vertical link to the throttle bodies themselves. Later engines do not have this link fitted.

The 4AGZE remained as a 16 valve and is virtually identical to the previous model, but produces slightly more power. This was the final 4AGZE produced. Both engines were available in the AE 101 model only.

Fifth Generation (4AGE 95.5-99.5?)

The final generation of 4AGE is available in 20 valve variant only, and was released in May 1995. This engine is distinguished by black cam covers (surprise - 'black top') and features MAP sensored air flow measurement, otherwise it looks similar to the previous version. Power output is 123 kW and it is only available in the AE 111 Corolla series. This engine has a different intake air box to the earlier 20 valve and has rubber intake trumpets instead of the plastic ones of its predecessor. The throttle bodies are also slightly larger diameter.

GEARBOX TYPES (RWD)

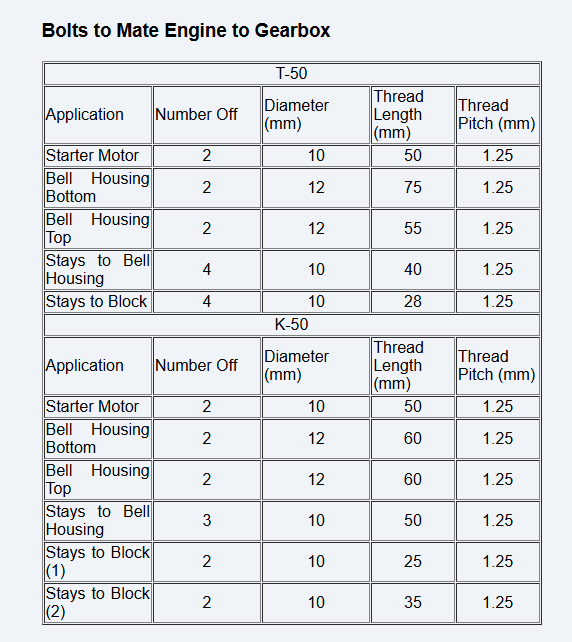

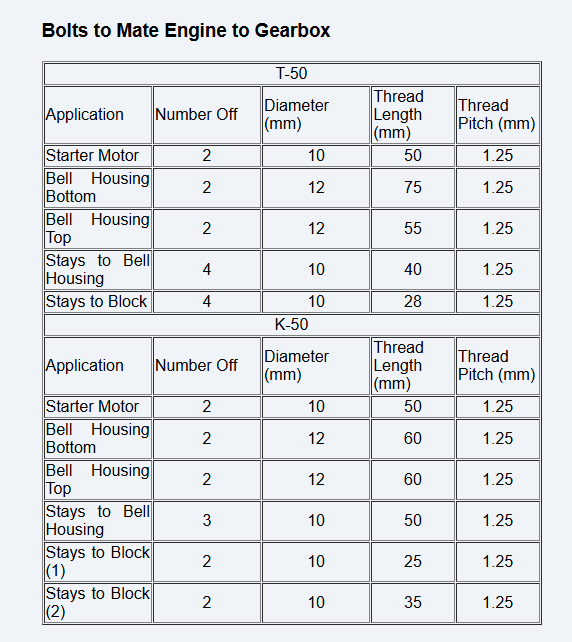

There are two RWD 5 speed gearboxes that will fit any 4AGE using factory parts, provided you have the right bell housing to mate the gearbox to the engine. These gearboxes are called the K-50 and T-50. There are also 4 speed versions of these gearboxes (called the K-40 and T-40) fitted to other Toyotas, so be careful to ensure you get one with the right number of gears...

T-50 Gearbox

The T-50 gearbox has a separate bell housing, utilises a hydraulic clutch and comprises 4 main alloy castings: bell housing, two diagonally split gear casings and a tail housing. This gearbox is often referred to as the ‘split case’ alloy 5 speed and weighs 29 kg. The ONLY bell housings that will mate a T-50 gearbox to a 4AGE come from a RWD 'A' series engine (3A/4A/4AGE).

The T-50 bell housing has letters cast externally into the top section between the uppermost bell housing to engine block bolt bosses that identify the engine it came from, ie 3A or 4AG etc. 3A and 4A bell housings have the clutch fork on the LHS while 4AG bell housings place it on the RHS.

The T-50 gearbox was fitted to other engines as well, such as 1S and 3T etc. The gearbox itself is identical, however, the bell housings differ to suit the parent engine. There are also two types of T-50 gearbox, referred to as 20 and 22 spline. This relates to the number of splines on the gearbox output shaft. There is also a difference in the diameter of the input shaft bearing, which is covered by the bell housing: 62 mm vs 68 mm. The 68 mm bearing is in the 22 spline gearbox. The 22 spline gearbox is more desirable as it is stronger. It is also what all RWD 4AGEs came with.

In general terms gearboxes made 1983 or newer are 22 spline. This means that 3T, 1S, 3A and 4A engines have 22 spline units. 2Ts are 20 spline - so be careful. The AE 85/86 and AA 63 series T-50 gearboxes are 650 mm long from the engine end of the bell housing to the centre of the gear lever mount, however, apparently some tail shaft housings fitted to earlier 20 spline gearboxes are shorter, hence allowing relocation of the gear lever with some mixing and matching of components. I have never seen one of these gearboxes.

In reality a 22 spline gearbox is the only one you can use because it is the only one that will mate correctly with an A series bell housing and handle the power.

K-50 Gearbox

The K-50 gearbox has an integral bell housing, utilises a cable clutch and comprises two main alloy sections: front casting with integral bell housing and the separate tail housing. There is also a pressed steel plate that bolts to the bottom of the front section.

The K-50 is normally found behind 3A 1500 cc SOHC engines fitted to AE 70 and AE 85 Corollas etc. The ONLY K-50 that will fit comes behind a 3A engine - Bell housings off any other motor will NOT fit a 4AGE. These gearboxes are all 20 spline.

The K-50 is ideal for 4AGE conversions into KP 61 Starlets or Escorts etc, ie cable clutch cars. Although it is not as strong as the T-50 you will probably get away with it in a light car with moderate power output and sane driving.

In either case ensure you get the corresponding bell housing front cover plate (that bolts to the back of the block just ahead of the flywheel) and the 2 cast stays that bolt between the bottom of the block and the lower portion of the bell housing. Apparently the rear crankshaft bearings can flog out if these are omitted.

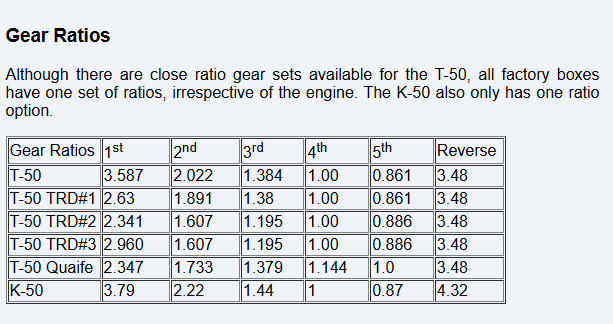

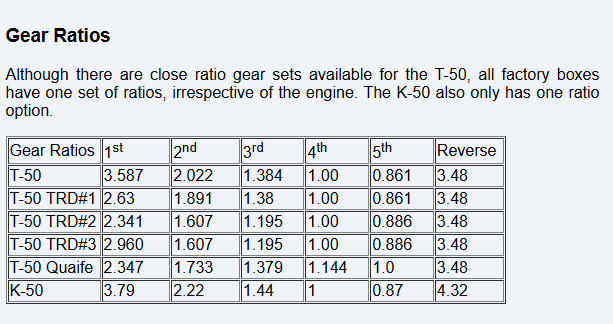

GEARBOX RATIOS (RWD)

Although there are close ratio gear sets available for the T-50, all factory boxes have one set of ratios, irrespective of the engine. The K-50 also only has one ratio option.

POWER HANDLING

As mentioned above there are two types of T-50 gearbox - 20 and 22 spline output shaft. The 22 spline gearbox is stronger and is capable of handling around 200 horsepower in a Lotus Seven type car (i.e. 600 kg) almost indefinitely – and often more, depending on the driving style.

The K-50 will handle the lesser powered 4AGEs in a normal weight car, however, the T-50 is recommended. The K-50 really comes into its own for easy conversion of Escorts, Starlets and early Corollas etc with cable clutches to 4AGE. Although the gear lever may require a new hole in the transmission tunnel it is quite likely the K-50 will bolt to the existing Starlet/Corolla gearbox cross member, requiring only engine mounts to be fabricated. (Note - the 4AGE will bolt into 3A sub-frames - and some KE 70 series Corollas came with 3A engines…)

I would certainly not recommend putting a K-50 behind a 4AGZE…

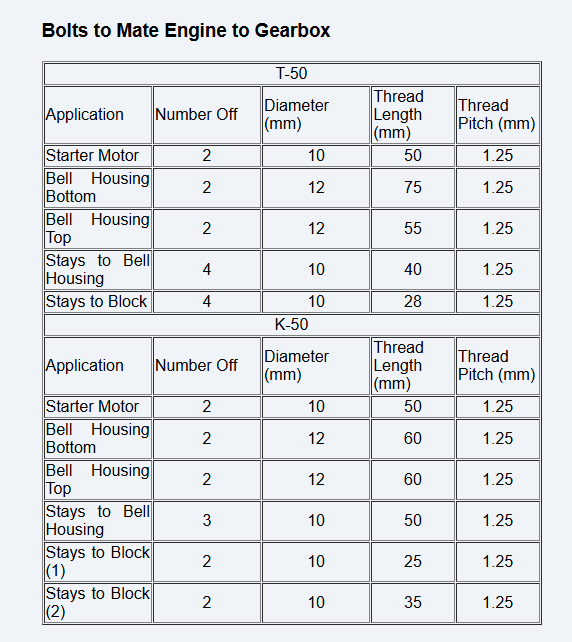

ENGINE TO BELLHOUSING BOLTS

The bolts are high tensile and quite expensive to buy new, so I suggest you buy the bare minimum you require. If the exact bolt sizes are not available, you may have to buy the next longest bolt and cut to size. Don't forget to use spring washers. Ideally get the factory bolts from a wrecker.

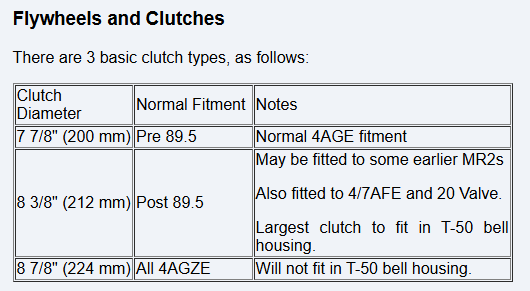

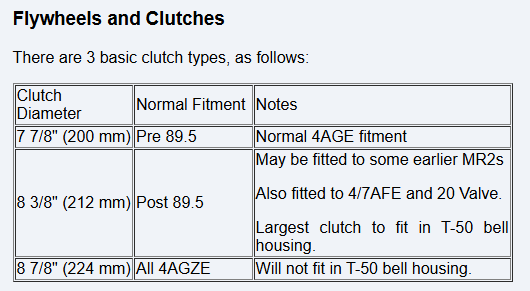

FLYWHEELS AND CLUTCHES

Clutches and flywheels are interchangeable between all 4AGE variants (beware that 4AGEs have 8 bolt flywheels compared to 6 bolt for the lesser family members), however, they must be changed as a unit - a 212 mm pressure plate will not fit the other flywheels.

The 200 and 212 mm clutches will fit a 22 spline T-50 gearbox and the clutches and flywheels fit inside the bell housing. The 200 mm clutch fits the K-50, but I am unsure if the 212 mm will. All the clutches fitted to the various 4AGEs will work with the standard T-50 release bearing etc. Use a 5/8" clutch master cylinder.

The 224 mm 4AGZE clutch and flywheel assembly will not fit inside the T-50 bell housing, and the 224 mm clutch plate has a larger diameter spline than the T-50 input shaft - in fact it fits the W-55 series ‘Supra’ gearboxes.

Spigot Bearing

Any FWD 4AGE will not have a spigot bearing in the back of the crank for the gearbox input shaft to mate with. It pays to check and replace if necessary. The standard RWD 4AGE bearing fits all 4AGEs. This bearing MUST NOT be omitted otherwise the front gearbox oil seal dies, you get an oil leak and have to pull the gearbox out to change it. The front gearbox bearing won’t like it either.

If you need to get an old bearing out the easiest way I know is to squirt/pack grease in through the centre of the bearing to fill the cavity behind it. This area is reasonably large so don’t be surprised when it seems to take forever to fill up. Then take a close fitting bolt, place it in the centre of the bearing and hit it with a hammer (several times). The hydraulic pressure will force the old bearing out. Don’t forget to use safety glasses etc.

Starter Motor

Easiest option is to use the starter motor that is correct for the gearbox, so make sure you buy it when you get the gearbox. Don’t forget the cover plate that goes between the back of the engine and the front of the bell housing too - you will have to remove the flywheel to get it. The 4AGZE starter motor is incompatible with RWD gearboxes. 20 valve or red top flywheels (they are the same) work just fine with AE 86 starter motors.

Speedo Drives

The standard speedo drive comes directly out of the gearbox tail shaft housing. If you have a really tight transmission tunnel then a VDO etc angle drive can be used to allow the speedo cable to lie parallel to the gearbox. Cheaper option is to look under automatic RWD Celicas etc – most had a factory angle drive that will mate with a T50. There are a couple of different angles available.

Speedometer Drive Corrections

If you change your overall tyre size or differential ratio, or mate the gearbox to a completely different speedo then you will need to make a speedo error correction. My thanks to Neil Fraser for the following information:

"The gearbox speedo worm drive ratios I know of include 5 x 19, 6 x 20, 6 x 22 etc. (ie 5 starts on the worm gear and 19 teeth on the driven gear). Most speedos are 637 rpk, 675 or 1000 rpk (revs per km). So lets say that to cover 1 km of distance your output shaft at the gearbox will turn how many revs?

Say a tyre diameter of 590mm: Circumference = 22/7 x .59 = 1.854m

Axle revs: 1000/1.854 = 539.37

Output shaft revs: 539.37 x 4.11 = 2216.8284

Say your speedo is 675rpk (should be written on back somewhere) - required speedo cable revs: 2216.83/675 = 3.284, so therefore best ratio is about 6x20 (3.33)

The small gear will have written on it the number of starts on the worm it would be compatible with (ie 5 or 6). Using a 5 start gear on a 6 start worm is always terminal. The worm slides off easy enough but requires practically stripping the whole gearbox…"

DIFFERENTIAL RATIOS

The 4AGE loves to rev. The factory RWD cars come with either a 4.1 or 4.3 differential ratio, 4.3 is recommended. For any car running a Ford Escort type diff 4.44 is the recommended ratio. If you take an AE 86 with a 4AGE for a drive and you find it is uninspiring check the axle code on the chassis plate - if it is T-292 it is 4.1 ratio. A car with a T-282 (4.3) ratio goes much better. If the last digit is a 3 or 5 then you have just found a limited slip diff. As a comparison the AE 111 20 Valve uses a 4.312 diff ratio.

Remember that a 0.86 5th gear combined with a 4.44 ratio diff is equivalent to a four speed gearbox with a 3.8 diff.

Any good tyre shop should be able to supply rolling diameter specs for the tyres it sells. If not then rolling diameter (excluding tyre squash due to car weight - which you can assume to be consistent) can be figured thus: tread width * aspect ratio gives side wall height. Multiply this by 2 (two side walls contribute to one diameter overall) and add to it the rim diameter.

Thus 195/60 x 14 equates to (195 x 0.6 * 2) + (14 * 25.4) = 589.6mm = 23.2 in. Multiply this by pi to give circumference = 3.1412 x 0.5896 = 1.85 metres, so for every revolution of the wheel the car moves by 1.85 metres.

My car does 6500 rpm in top gear at max speed - that is 6500/0.86 (fifth gear ratio) = 7558 drive shaft rpm. This in turn passes thru’ a 4.44 diff ratio, so divide 7558 by 4.44 to give 1702 axle rpm. This means that a wheel is doing 1702 rpm, which is 1702 * 1.85 = 3149 metres/minute.

Multiply by 60 (minutes in hour) then divide by 1000 (metres in kilometre) and you get 188.95 kilometres/hour speed, which if you divide by 1.62 gives 116.6 mph. My car indicates 115 mph at this speed - not bad speedo calibration huh?

To compare a 185/70 x 13 tyre (what I used to have): (185 * 0.7 x 2)+ (13 * 25.4)= 589.2 mm diameter vs 589.6 mm for a 14 inch 60 profile - pretty close to the same, especially once tread wear occurs.

A friend runs the same box and diff as me, but 185/60 x 13 tyres: (185 * 0.6 x 2) + (13 x 25.4) = 552.2 mm diameter vs my 589.6: now divide one by the other: 552.2/589.6 = 0.936 ie his diameter is 0.936 or 93.6% of mine. Since this directly relates to engine rpm, and our gear ratios are the same (otherwise you have to account for these in the same way) his engine will do 1/0.936 more rpm at the same speed in the same gear = 6940 rpm.

Alternatively if I put his wheels on my car, my speed would drop to 116.6 * 0.936 = 109.1 mph at the same revs (6500).

CONCLUSION

This article covers the bulk of what I have learned about these engines over the past nine years, and hopefully will make your life a lot easier than mine was when I was starting out.

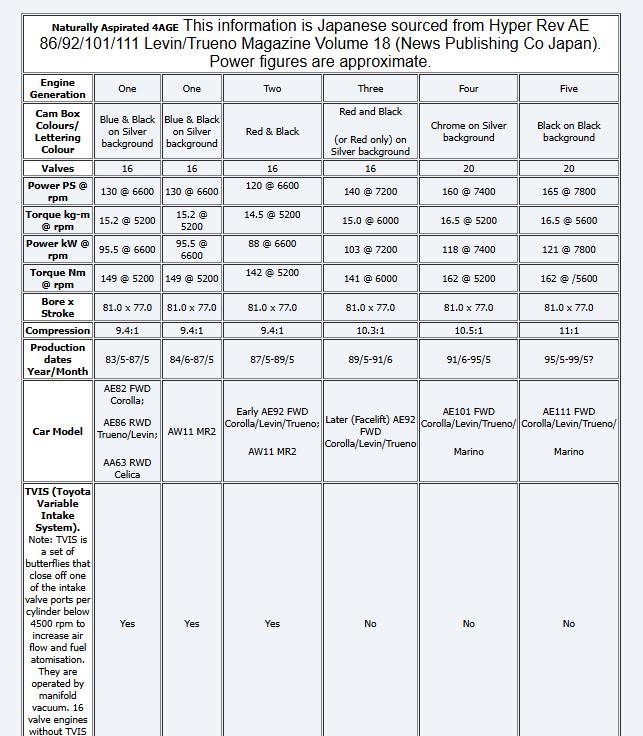

ENGINE VARIATION TABLE

all credits to Phil Bradshaw, put here by @lmtd9186